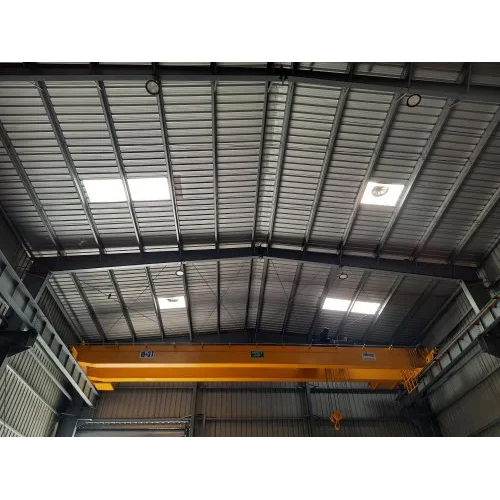

Double Beam EOT Crane

Product Details:

- Power Source Electric

- Condition Yes

- Usage INDUSTRIAL APPLICATIONS

- Crane Type Double Girder Crane

- Application Construction, Outdoor Yard

- Product Type Double Beam EOT Crane

- Loading Capacity 30-40 ton Tonne

- Click to view more

Double Beam EOT Crane Price And Quantity

- 1250000.00 INR/Unit

- 1 Unit

Double Beam EOT Crane Product Specifications

- Remote Control

- INDUSTRIAL APPLICATIONS

- Double Beam EOT Crane

- Construction, Outdoor Yard

- Electric

- Yes

- Double Girder Crane

- Yellow

- 30-40 ton Tonne

Double Beam EOT Crane Trade Information

- 7 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

A Double Beam EOT Crane includes the following important characteristics and elements:

1. Two parallel girders that cover the breadth of the working area make up the crane's structure. The crane is primarily supported by the girders, which are normally built of steel.

2. End trucks: The end trucks are the structures that hold the wheels or tracks that allow the crane to move along the runway system. They are situated at each end of the twin girders. They give the crane construction stability and support.

3. Hoist: A trolley with the hoist mechanism attached on it moves along the twin girders. The lifting and lowering of the cargo is done by the hoist. Depending on the unique requirements, double beam EOT cranes can be fitted with a variety of hoists, including wire rope hoists and chain hoists.

4. Trolley: Mounted on the two girders, the trolley moves horizontally along the crane's length. It supports the hoisting system and enables accurate load location.

5. Control system: Double Beam EOT Cranes are frequently fitted with a control system that gives operators full command over the crane's movement and use. Features like pendant controls, radio remote controls, and variable speed controls could be included of the control system.

6. Safety features: Double Beam EOT Cranes are outfitted with a variety of safety features to ensure safe operation. These could consist of audible or visual alerts, limit switches, emergency stop buttons, overload protection, and anti-collision systems.

7. Customization is possible with Double Beam EOT Cranes to fulfil particular needs and applications. Different load capacities, spans, lifting heights, and operating speeds can be incorporated into their design. Additionally, they can be fitted with features like automated controls, sophisticated monitoring systems, and auxiliary lifting mechanisms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry  English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free