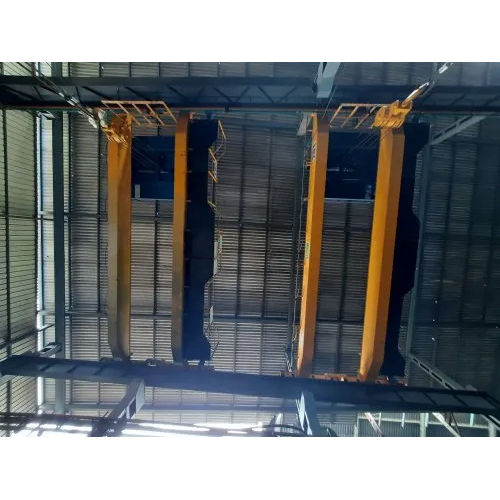

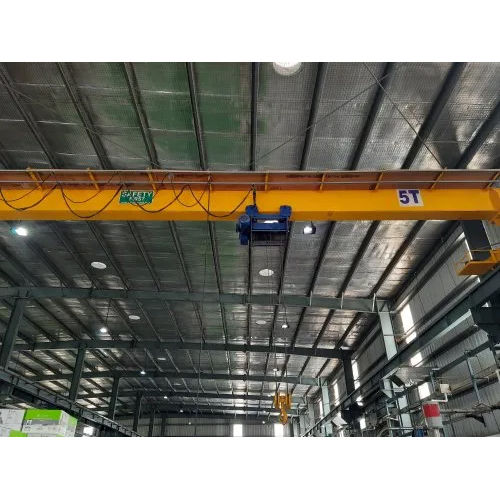

Box Girder EOT Cranes

350000 INR/Unit

Product Details:

- Usage Construction

- Color Yellow

- Product Type Box Girder EOT Cranes

- Emergency Stop Yes

- Application INDUSTRIAL

- Condition New

- Power Supply Electric

- Click to view more

X

Box Girder EOT Cranes Price And Quantity

- 1 Unit

- 350000 INR/Unit

Box Girder EOT Cranes Product Specifications

- New

- INDUSTRIAL

- Yes

- Electric

- Box Girder EOT Cranes

- Yellow

- Construction

Box Girder EOT Cranes Trade Information

- 7 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

An Electric Overhead Traveling (EOT) crane is a type of crane that operates on an elevated runway system, usually attached to the ceiling of a facility or supported by freestanding columns. A box girder EOT crane refers to a specific design of the crane where the main bridge girder is in the form of a box section.

Here are some key features and components of a box girder EOT crane:

1. Box Girder Design:

The main horizontal beam of the crane, known as the bridge girder, is in the form of a box section. This box girder design provides increased strength and rigidity, allowing for efficient load-bearing capabilities.

2. End Carriages:

The box girder is supported by end carriages at both ends. These carriages house the wheels on which the crane travels along the runway.

3. Hoist and Trolley:

The hoist is the lifting mechanism of the crane, and it is mounted on a trolley that moves along the length of the bridge girder. This arrangement allows the crane to lift and transport loads horizontally.

4. Runway System:

The crane moves along a fixed runway system, which can be installed on the ceiling or supported by columns. The runway provides a path for the crane to travel, allowing it to cover the entire working area.

5. Motor and Controls:

Electric motors power the movement of the crane, including the hoist, trolley, and bridge travel. The control system enables precise and efficient operation, allowing the operator to control the crane's movements.

6. Capacity and Span:

Box girder EOT cranes are designed to handle a wide range of load capacities and spans. The capacity of these cranes can vary from a few tons to several hundred tons, depending on the application.

Applications of Box Girder EOT Cranes:

1. Steel Industry:

Box girder EOT cranes are extensively used in steel mills for handling and transporting heavy steel coils, sheets, and other raw materials. They play a crucial role in the production and processing of steel.

2. Automotive Manufacturing:

In automotive manufacturing plants, these cranes are employed for lifting and moving large components such as car bodies, engines, and other heavy parts during assembly processes.

3. Shipbuilding and Maritime Industry:

Box girder EOT cranes are used in shipyards for lifting and placing heavy ship components, including sections of the hull, ship engines, and other materials required in the shipbuilding process.

4. Power Plants:

EOT cranes with box girder designs are utilized in power plants for tasks such as the installation and maintenance of heavy machinery, boilers, turbines, and other equipment.

5. Construction Sites:

These cranes are employed at construction sites for lifting and placing heavy construction materials, prefabricated components, and equipment.

6. Foundries:

Foundries use box girder EOT cranes for handling molten metal ladles, molds, and other heavy materials involved in the casting process.

7. Aerospace Industry:

In the aerospace sector, EOT cranes with box girders are used to handle large and heavy components of aircraft, such as wings, fuselage sections, and engines, during the manufacturing and assembly processes.

8. Material Handling Warehouses:

Large warehouses and distribution centers utilize box girder EOT cranes for efficiently moving and stacking heavy pallets, containers, and materials.

9. Paper Mills:

Paper manufacturing facilities use these cranes for lifting and transporting heavy paper rolls and other materials throughout the production process.

10. Mining Industry:

Box girder EOT cranes are employed in mining operations for handling heavy loads, such as ore and equipment, in various stages of the mining and mineral processing activities.

11. Railway Maintenance Facilities:

EOT cranes are utilized in railway maintenance yards for lifting and positioning railway cars and heavy components during maintenance and repair work.

12. Wind Energy Sector:

In wind turbine manufacturing and maintenance, box girder EOT cranes assist in handling large and heavy components, such as tower sections, nacelles, and blades.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese